NASZE PRODUKTY

Ściernice ceramiczne

Dowiedz się więcej

o naszym produkcie

Ściernice o spoiwie ceramicznym służą najczęściej do precyzyjnego szlifowania płaszczyzn, wałków, otworów, profili a także ostrzenia narzędzi skrawających, prac warsztatowych i do zgrubnej obróbki metali.

Nowoczesne, syntetyczne ziarna ścierne stosowane w narzędziach Abras umożliwiają uzyskanie wysokiej powtarzalności ściernic. W zależności od rodzaju i charakterystyki obrabianego przez klienta materiału dobieramy narzędzia o odpowiedniej kombinacji 3 kluczowych parametrów:

- typu ziarna ściernego (elektrokorundy, elektrokorund szlachetny, węglik krzemu, monokorund i inne)

- wielkości ziarna ściernego, która wpływa bezpośrednio na uzyskiwaną chropowatość powierzchni,

- typu i twardości spoiwa, która określa wielkość siły potrzebną do wyrwania ziarna z otaczającego go spoiwa.

Z tego względu dobór odpowiedniej ściernicy wymaga sprecyzowania następujących parametrów:

- kształt i rodzaj obrabianego materiału (typ i twardość)

- naddatek do usunięcia i powierzchnia styku operacji szlifowania,

- wymagany stopień wykończenia powierzchni (chropowatość),

- wymiary ściernicy,

- typ, prędkość robocza oraz moc maszyny,

- rodzaj stosowanego chłodziwa,

- sposób profilowania (obciągania) ściernicy.

Zamów wizytę doradcy technicznego

Wybrane produkty

Poniżej prezentujemy wybrane ściernice wraz z typowymi przykładami zastosowań.

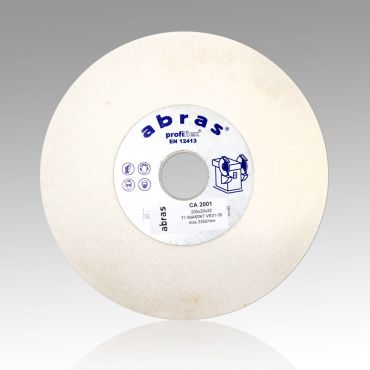

Ściernica ceramiczna abras

300x32x32mm

Zdjęcie produktu

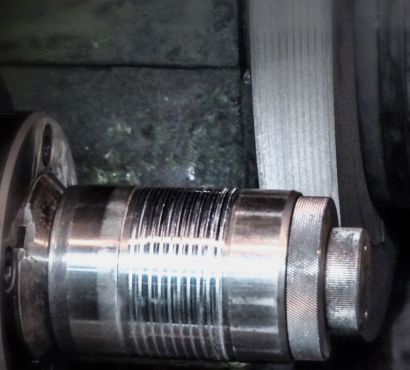

Otwieranie struktury segmentów diamentowych

Ściernia ceramiczna abras T1-99A60K70VE01-35

200x20x32

Zdjęcie produktu

Ostrzenie wierteł

Ściernica ceramiczna abras T1-99A60K7-VE01-35

450x50x203

Zdjęcie produktu

Profilowanie pierścieni tłokowych

Ściernica ceramiczna abras

400x50x127

Zdjęcie produktu

Szlifowanie precyzyjne CNC